|

The electrical strain gauge |

Automatic strain measurement is usually done with an electrical resistance strain gauge (or gage). It looks like this:

A thin plastic base supports thin ribbons of metal, joined in a zig-zag to form one long electrically conductive strip. The entire device is typically 10 mm long, with 16 or more parallel metal bands. When the plastic is stretched the wires become longer, and thinner. The electrical resistance therefore increases. The % increase is about twice the % extension, because if the wire is stretched to twice its original length the electrons have to struggle twice as far through a conductor of half the original cross section. There are other influences on this "gauge factor" so the manufacturer kindly prints the exact multiplication factor on the wrapper.

All we need now is an ohm meter and some epoxy glue to fasten the plastic securely to the material whose stretch is to be investigated. There are, however, some small, and some major details that will vastly improve the accuracy of measurement and impress referees.

The most major detail of all is that strain gauges can hardly be strained at all! Different materials have different limits but about 1% extension is the limit for reliable performance.

If you have been using a vernier to check the shrinkage of the planks on your hen-house you cannot just substitute an electrical strain gauge. The movement at the gauge has to be reduced somehow, and made uniform over the length of the sensitive strips on the gauge.

This is done by glueing the gauge somewhere on a flexible beam which has one end fastened securely to one plank and whose outer end is somehow following the movement of the next plank.

The length and thickness of the beam are chosen so that the expected movement between the planks will cause an extension, or compression of the gauge which is less than about 1%.

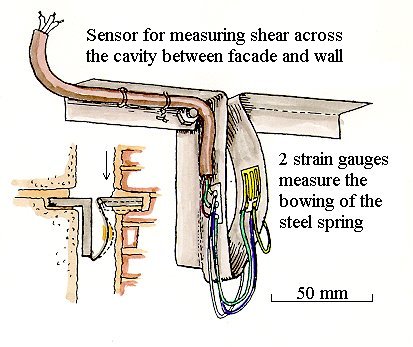

The principle of the bending beam can be adapted to all kinds of situations. Here, for example, is a device that I made to measure the expansion of the facade of a building whose artificial stone facing was connected by steel pins across a gap to a massive brick wall. The stainless steel strip changes its radius of curvature as the facade moves up and down by about 1,5 mm during the day.

The support for the gauge is usually stainless steel or an aluminium alloy. It is often difficult for ordinary people to get the specialised alloys. The aluminium extrusions found in hobby and do-it-yourself stores are OK. Suitable stainless steel beams can be found as flexible spatulas in kitchen equipment shops and as palette and painting knives in art shops. Two part epoxy glues are suitable adhesives, acrylic and rubber based glues creep too much.

Strain gauges can be adapted to all sorts of measurements and are often the cheapest and simplest technique for automating collection of non-mechanical data. A standard RH sensor, for example, uses a strain gauge to sense the change in length of a ribbon of moisture sensitive plastic. Strain gauges, once has got the hang of using them, are extraordinarily useful experimental devices. They are also cheap, once one has acquired the specialised resistance measuring box which is necessary because of the relatively small change of resistance that must be measured accurately. The manufacturers of strain gauges give good advice on the geometry of beams, the details of gluing without bubbles and wiring to reduce the effect of temperature on the measurement (metals change resistance with temperature as well as with extension).

There are other strain measuring and detecting devices. Building conservators use brittle plates that are designed to break all at once, or plastic foils with a sequence of conductive strips that break in sequence. These are put across cracks in Cathedral vaults to reinforce the urgency of appeals for repair funds.

Brittle paint is fun to use and has been repeatedly reinvented by modern artists. Paint that alters the plane of polarisation of light as it is stretched gives impressive colour displays that show the points of high strain in complex machine parts.

There is another important use of strain gauges: to measure stress.

This work is licensed under a Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.